Your Additive/CNC Manufacturing and Urethane Casting Center

Offering One-off parts, low-volume production runs to turn-key assemblies using our various manufacturing methods from CNC Machining, Sheet metal fabrication, additive manufacturing and 3D prototyping processes.

With roots based in Southern California since 1986

As a California based single source provider, bringing your idea to reality.

-

SLA (Stereolithography)

SLA (Stereolithography)--Stereolithography (SLA) is a 3D printing process that uses ultraviolet light to cure liquid resin into solid objects. It involves a machine called a stereolithography apparatus that converts liquid plastic into solid forms, typically creating models and prototypes layer by layer.

-

Selective Laser Sintering

Selective Laser Sintering--Selective Laser Sintering (SLS) is an additive manufacturing technology that utilizes a high-energy laser to sinter thermoplastic polymer powders. The process constructs objects layer by layer by directing the laser to trace each cross-sectional geometry onto a powder bed.

-

Fused Deposition Modeling

Fused Deposition Modeling -- Fused Deposition Modeling (FDM) is an additive manufacturing technique that fabricates objects by heating and extruding thermoplastic filaments through a precision-controlled nozzle. The material is deposited layer by layer according to the geometry defined in the digital model. FDM is valued for its affordability, broad material compatibility, and simplicity of operation. Commonly used thermoplastics in this process include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and TPU (Thermoplastic Polyurethane).

-

CNC Machining

With over 30 years of experience, Dynamo Innovations CNC high precision machine department has provided exceptional service for a variety of industries.

-

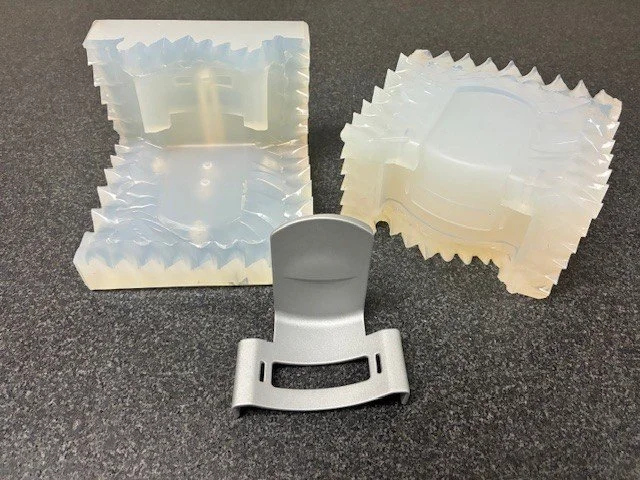

Urethane Services

Urethane Casting--Urethane casting, also known as vacuum casting, is a low-volume manufacturing technique ideal for producing custom parts. It serves as a cost-effective substitute for injection molding, making it especially suitable for prototyping, limited production runs, and specialized applications such as artistic fabrication.

-

HQ/Finishing

Dynamo Innovations’ quality and finishing department offers finishing services from simple “strip-and-ship” to full assembly “show quality capabilities.”

-

High Resolution Printing

Using state-of-the-art machinery, Dynamo Innovations brings out the power of manufacturing with PolyJet, Formlabs Form 3L, Figure 4 and more.

WHO WE ARE

WHAT WE DO

How It Works

We guide you through the entire process, from conception to completion.

Concept Prep

Discovery of ideas and brainstorming

Building

Putting the idea to work with precision construction

Quality Control

Discovery of ideas and brainstorming

Launch

Project signed off and running